Recently, the research group of Prof. Ying Bai from the School of Physics and Electronics has made new methods in composite Li metal anode for the advanced lithium-ion battery. The related paper entitled Defect-abundant commercializable 3D carbon papers for fabricating composite li anode with high loading and long life has been published in Energy Storage Materials. The doctoral Du Pan is the first author, Dr. Yong-Sheng Hu and Prof. Ying Bai are the corresponding authors.

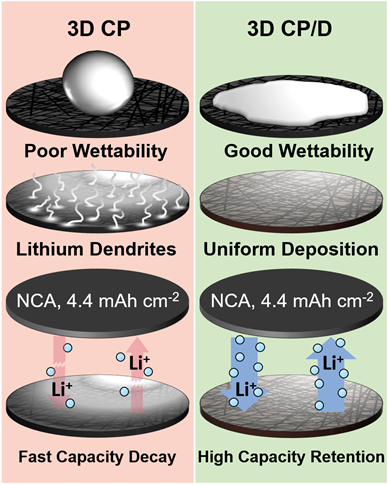

Figure 1. Schematic diagram for the advantages of oxygen treated 3D CP/D over the untreated pristine 3D CP in improving the electrochemical performances.

Lithium metal is considered as the most promising anode material due to its high theoretical specific capacity and low electrochemical reduction potential. However, both lithium dendritic formation and huge volume change upon cycling severely discount its practical longevity. Herein, abundant structural defects were successfully introduced into the commercial 3D carbon paper (3D CP), which was then employed as the matrix (3D CP/D) to construct Li composite anode (3D CP/D-Li). Experimental observations reveal that the oxygen treatment greatly improves the lithiophilicity of 3D CP/D, which not only enables the uniform loading of molten lithium, but also facilitates lithium stripping and plating upon cycling. Symmetric cells with the 3D CP/D-Li could be operated over ~ 600 cycles under an ultrahigh current density of 12 mA cm−2. Utilizing commercial LiNi0.8Co0.15Al0.05O2 (NCA) as cathode material (with a high mass loading of ~ 21.93 mg cm−2), the assembled cell (NCA | 3D CP/D-Li) exhibits an improved capacity retention of 74.4% and a high reversible capacity of 160.2 mAh g−1 after 500 cycles compared with that selecting bare lithium as anode (34.4% and 72.2 mAh g−1). The generated 3D CP/D matrix was found very attractive as commercial anode owing to the following aspects (Figure 1): 1) mitigating metal dendrite formation by highly lithiophilic active sites, which facilitate Li+ stripping/plating on electrode surface; 2) suppressing SEI growth contributed by the enhanced Li+ surface kinetics and the generation stable surface; 3) demonstrating high mass loading, high rate performances, high energy density and high stability in thus fabricated cells.

All these advantages indicate the promising perspective for 3D CP/D framework as a desirable matrix for constructing 3D lithium anode. In addition, the strategy to obtain lithiophilic 3D CP/D substrate might provide some innovative insights for the future large-scale application of metallic lithium anode, covering LIBs as well as high-energy-density Li-S, Li-O2 batteries and even other secondary energy storage and conversion systems.

The research work is supported by the general project of the National Natural Science Foundation of China, the Zhongyuan Thousand Talents Program of Henan Province, the Henan Overseas Expertise Introduction Center for Discipline Innovation, the Program for Innovative Research Team in Science and Technology in the University of Henan Province, and Science and Technology Development Project of Henan Province.

Energy Storage Materials is a well-known journal owned by Elsevier, which mainly publishes the latest scientific research progress in the field of materials science and nanotechnology. The latest impact factor of the journal is 17.789.

Link: https://www.sciencedirect.com/science/article/pii/S2405829722002975?dgcid=coauthor

Recoures: School of Physics and Electronics

Research /

Research Achievements /

Science & Technology /

School of Physics and Electronics /

Content

Research /

Research Achievements /

Science & Technology /

School of Physics and Electronics /

Content